Dust Collector Spark Trap

Dust Collector Spark Trap

All Spark Traps Are Not Created Equal!

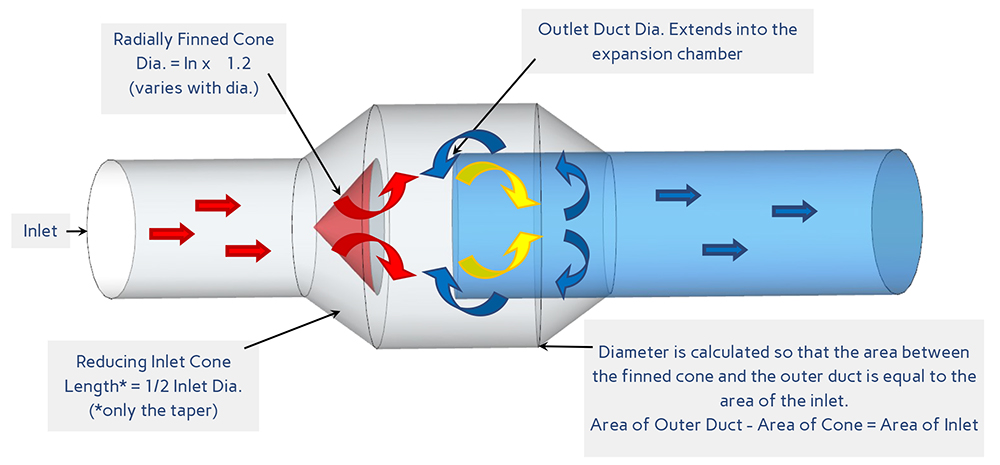

Looking inside, the problem with most spark traps is they simply swirl the air. Well, that isn’t a problem

anymore with U.S. Duct’s new spark trap. Its patented technology “tumbles” the ember through a “Tortuous

Path” forcing contact with more oxygen, and allowing more time for the spark to burn out.

Because of the custom cone and the outlet

inset design, our spark trap effectively

eliminates sparks before they can exit the trap

and thus, it can be installed right at the dust

collector, adding convenience and eliminating

distance requirements!

Looking inside, the problem with most spark traps is they simply swirl the air. Well, that isn’t a problem

anymore with U.S. Duct’s new spark trap. Its patented technology “tumbles” the ember through a “Tortuous

Path” forcing contact with more oxygen, and allowing more time for the spark to burn out.

Because of the custom cone and the outlet

inset design, our spark trap effectively

eliminates sparks before they can exit the trap

and thus, it can be installed right at the dust

collector, adding convenience and eliminating

distance requirements!

While a lot of spark traps may look the same on the outside, it’s what’s on the inside that counts. Know the difference and contact Environmental Solutions to get the real Spark Trap from U.S. Duct!

CALL TOLL FREE 1-866-438-7891

Mitigating Dust Collector Fire Risks from Sparks

Fire Risk Prevention Measures

In modern industrial plants where welding, grinding, machining, or other processes produce potentially combustible dust, mist, or fume, maintaining a clean and safe work environment becomes a top priority. Assessing and addressing the fire risks in your facility should be part of your hazard analysis and prevention plan.

According to Donaldson Torit, this may include in-line spark abatement devices located within the air intake duct. One type of device creates turbulence in the air steam that cools and arrests most sparks without the use of water or chemicals. U.S. Duct’s Spark Trap does all the extinguishing in the chamber because it tumbles the air, requiring it to reverse on itself twice.

The extreme turbulence and the time in which the spark is held in the turbulence accounts for the effectiveness of the unit. This optional equipment may be worth considering as part of your fire risk mitigation strategy.

US Duct's Patented Spark Trap Technology

Spark Trap Key Features

- Uses a finned cone to create a swirling chamber to extinguish the spark before allowing it to pass through the spark trap

- .8”SP when velocity is sized for 3200fpm

- Can be ran at higher velocities but static pressure will increase

- Can be installed horizontally or vertically

- Hinged access door for easy cleaning

- Optional dropout kit for heavy-loading applications

- No minimum or maximum distance for install. Can be installed anywhere in the system

US Duct's Spark Trap in Action - Capturing Grinding Sparks!

Since US Duct’s spark trap effectively eliminates sparks before they can exit the trap, it can be installed right at the dust collector, adding convenience and eliminating distance requirements! Other spark reduction options may require a minimum distance from the collector, making it difficult to add a spark trap to an existing system and requiring multiple traps or extinguishing points.

7 Reasons to Choose The Real Spark Trap from US Duct

- Proven spark mitigation

- Greatly reduced damage to filter media

- Minimal pressure drop

- Zero footprint/space requirement

- Works in a vertical or horizontal position

- No secondary dust accumulation point

- No distance installation requirements (can be placed at the collector)

Customers also viewed: Raptor® Fire and Explosion Prevention, Fire Isolation & Diversion, Dust Collector Explosion Vent Panels, Dust Collector Explosion Isolation and Diversion Valves, and Grain Elevator Monitoring, and Fire and Explosion Mitigation.